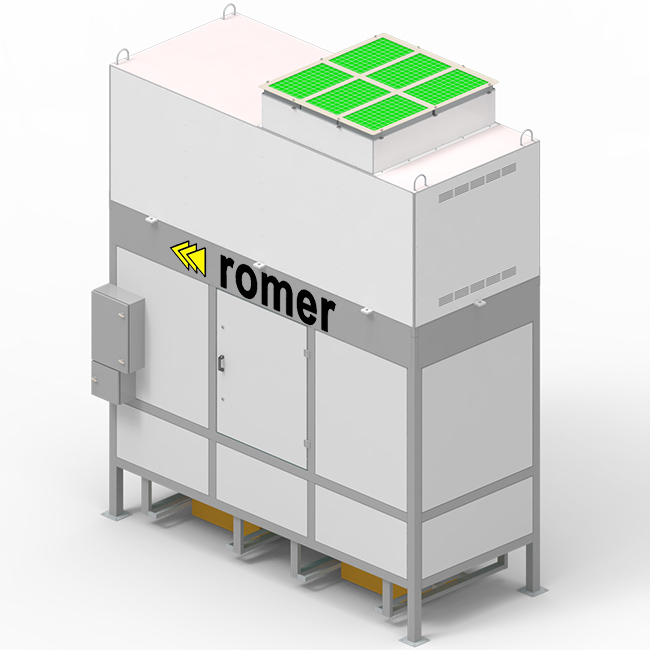

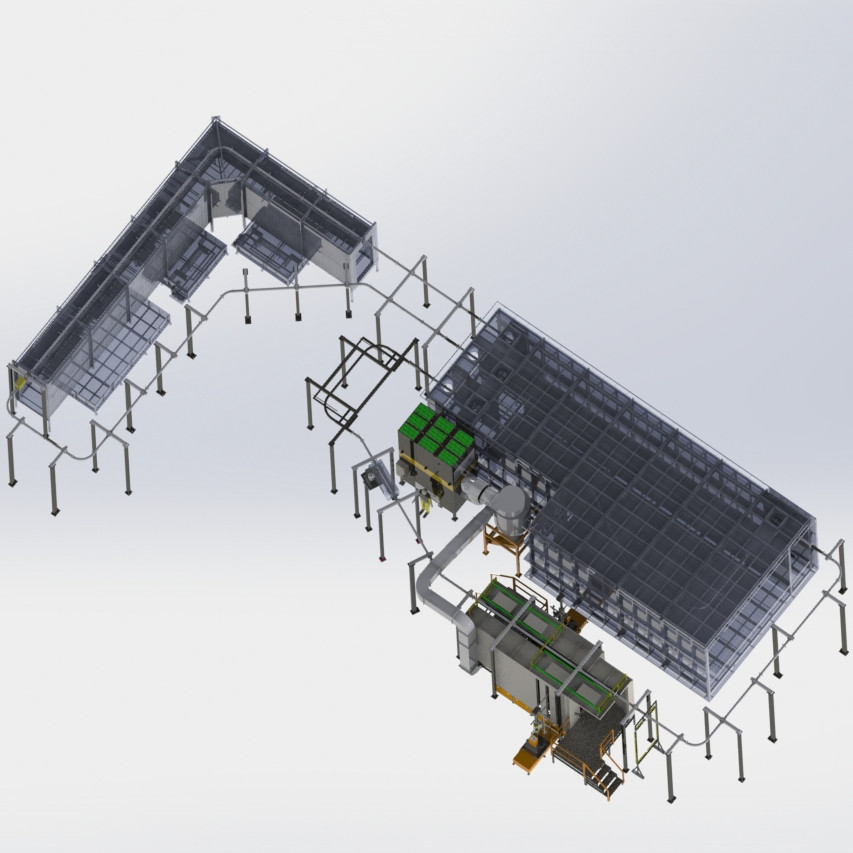

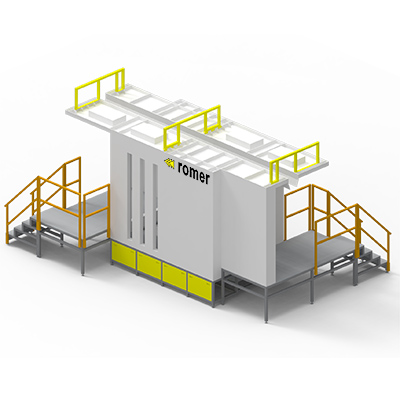

RP-01 Vacuum powder pump operating in HDC technology

The RP-01 powder pump is designed to transfer powder paint with the use of low air volume (also powdered enamel).

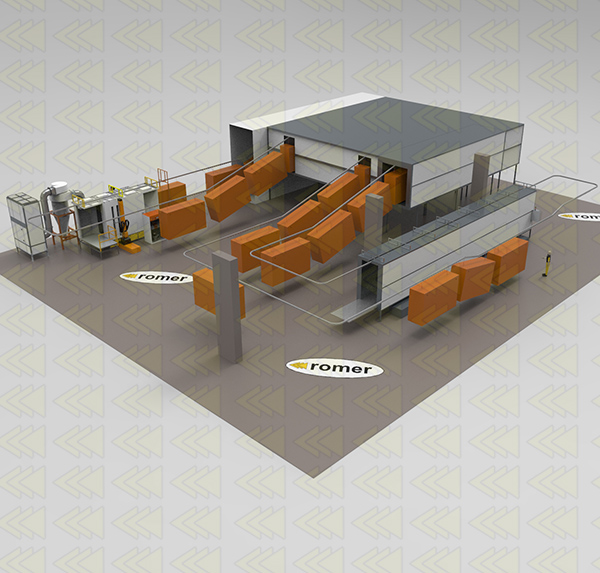

The RP-01 powder pump is applicable both to the transmission of fresh powder in automatic lines,

as well as for general transfer of paint from powder tanks

This pump is designed to transport large amounts of powdered paint, even over relatively long distances.

The individual valves of the powder pump are controlled by a computer control system - PLC.

| Efficiency with up to 8m of hose | 5kg / min |

| Efficiency at 9-16m of hose | 4kg / min |

| Efficiency at 17-25m of hose |

3.5 kg / min |

|

• Transports paint over long distances, even with large height differences |

|

| • Transport of paint with a small amount of air (HDC technology) | |

| • Cleaning the hoses in both directions, ie suction and delivery | |

| • Low operating costs compared to other venturi pumps | |

| • Control from the panel level or integration with the control of the powder center by the ModBus protocol |

RP-01 Vacuum powder pump with HDC technology

Powder pump RP-01 is designed for the delivery of powder paint (also powdered enamel) using very little air.

The RP-01 Powder Pump applies both to the transmission of fresh powder in automatic plants,

as well as for general transport of paint from powder tanks

This pump was designed to transport large volumes of powdered paint, even at relatively large distances.

The individual valves of the powder pump are controlled by a computer control system - PLC.

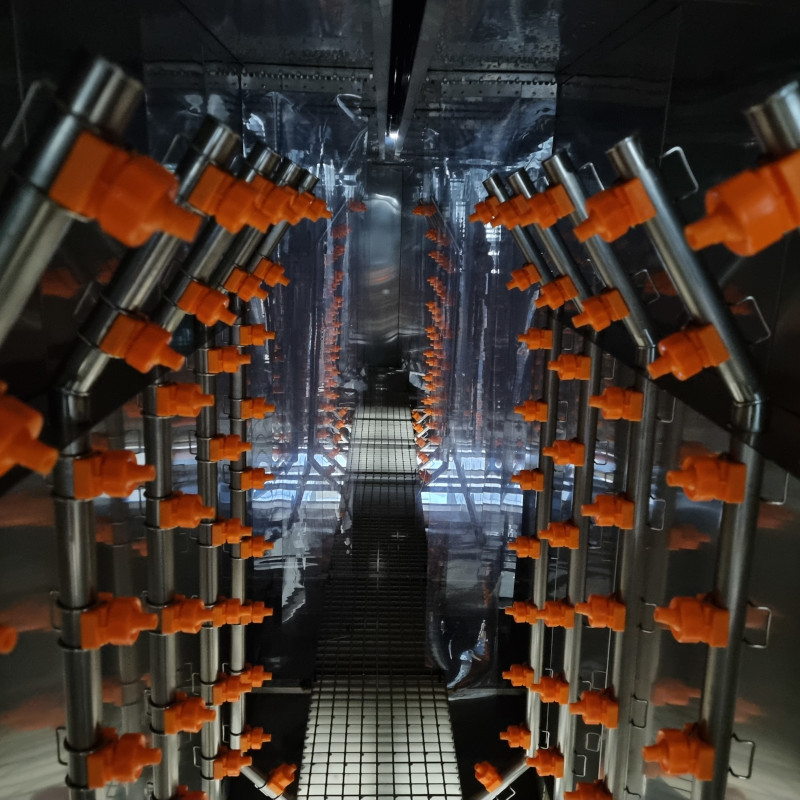

Principle of operation

In the powder chamber, a vacuum is generated. As a result, the powder paint is sucked into the chamber. The filter element separates the paint,

The powder chamber is closed on the output side by a diaphragm valve. The diaphragm valve on the inlet side of the powder chamber is closed, while the diaphragm valve on the outlet side is open. The paint is blown in the powder chamber by overpressure of the compressed air entering

by the filter element and in the final phase of the paint transfer. The suction and transfer procedure is alternated between the two powder chambers.