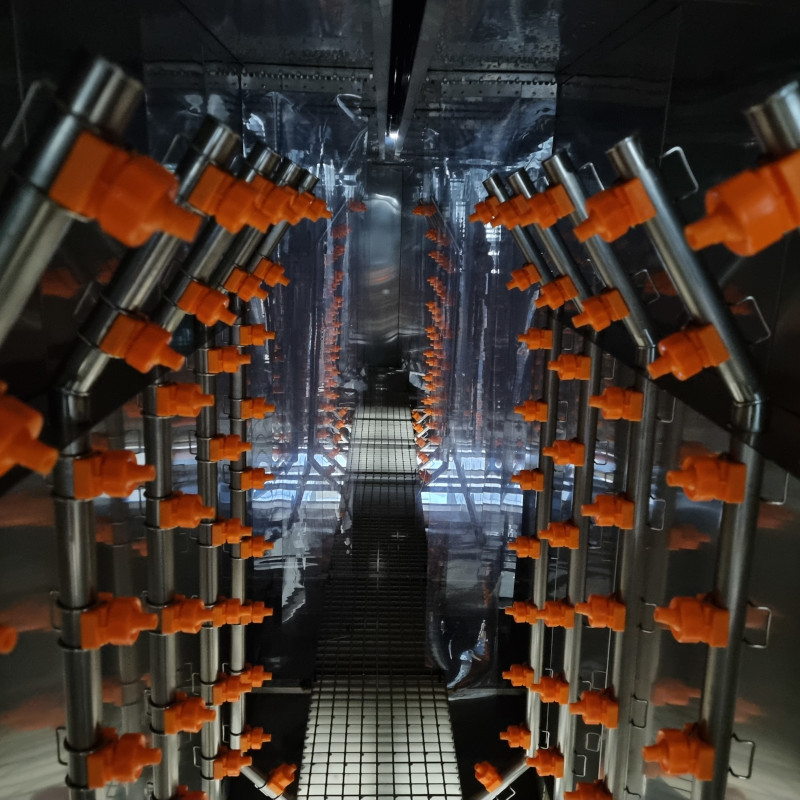

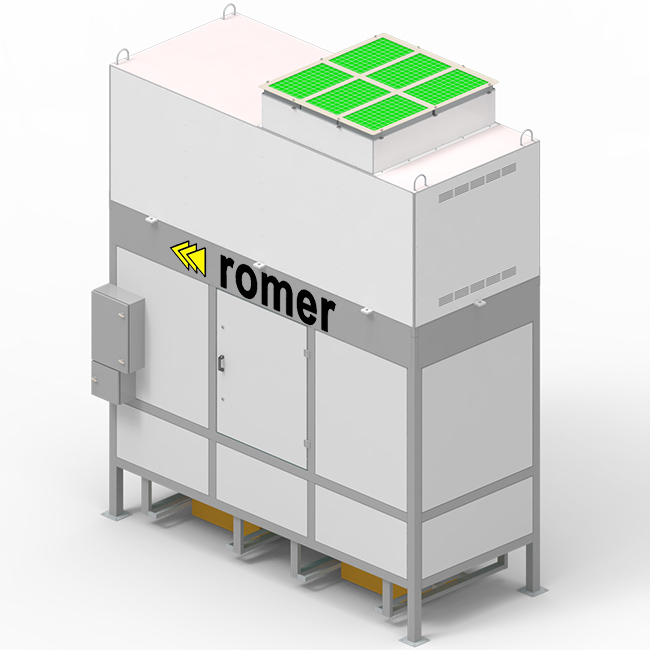

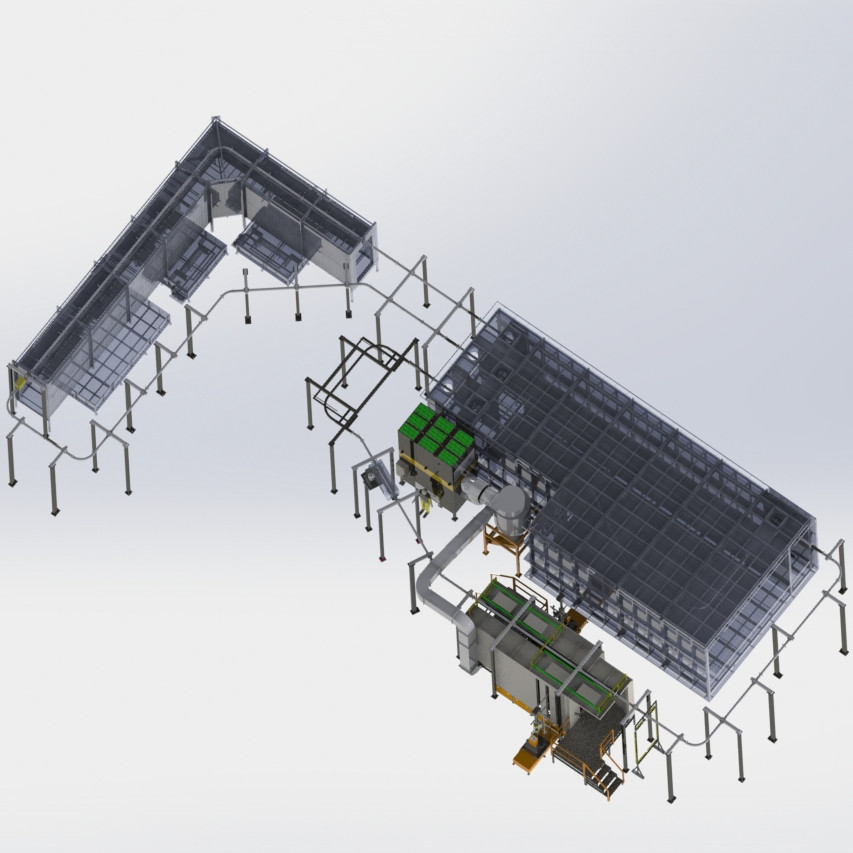

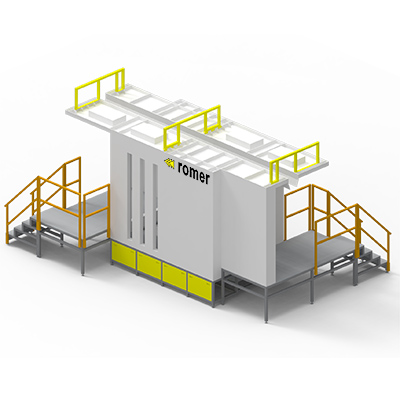

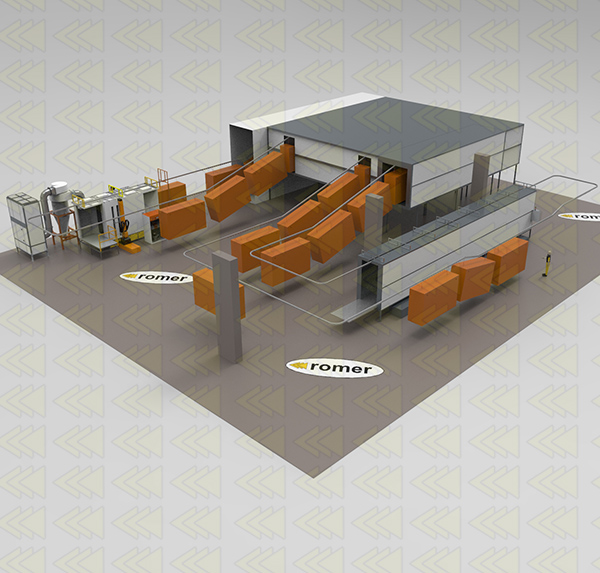

Ovens are designed for heating elements painted with powder paint. Heating occurs by continuous forced air circulation by fan system or by gravitational air circulation. During annealing the powder melting occurs, and on surface of a homogeneous structure of the paint well connect with the ground. Our ovens can be used for drying after washing metal objects in inert washing baths. Stable temperature and a wide range of adjustment at the time of melting make it useful for any kind of powder paint.

Ovens