|

Nízká cena |

Nízké provozní náklady |

|

|

|

|

|

|

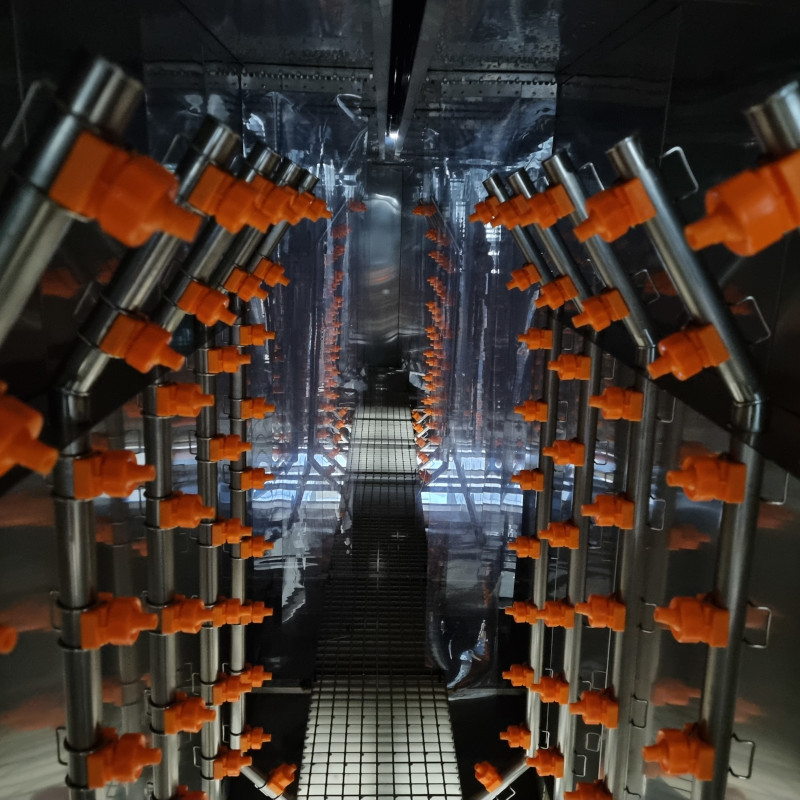

Zámky odolné proti výbuchu

|

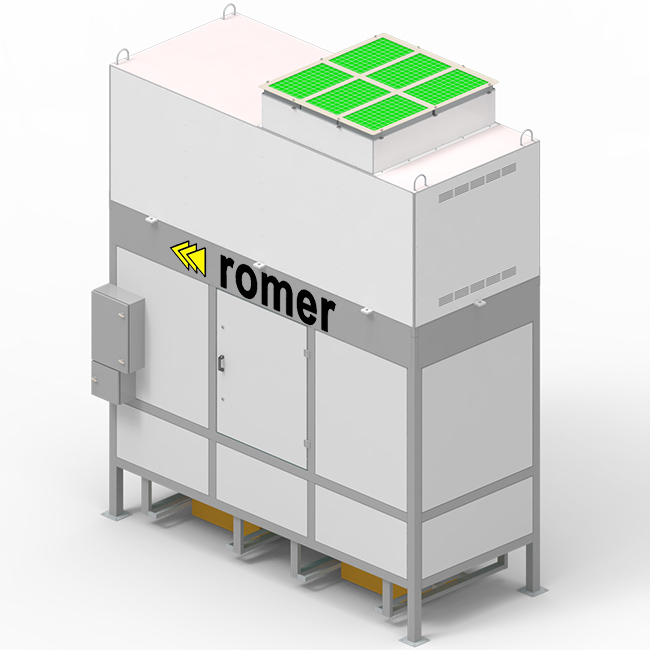

Gravitační topný systém |

| Série | Seria SL | Seria SL | Seria SW | Seria SW | Seria SW |

| Napájení | Elektřina | Elektřina | Olej | NG / LPG | NG |

| Nucená cirkulace vzduchu | ✔ | ✔ | ✔ | ✔ | ✔ |

| Dvoukanálový USB záznamník teploty | ✔ | ✔ | ✔ | ✔ | ✔ |

| Počet teplotních čidel | 1 | MTS 2+ | MTS 3+ | MTS 3+ | MTS 2+ |

| Tloušťka stěny (mm) | 80 | 240 | 240 | 240 | 240 |

| Tloušťka stropu (mm) | 80 | 300 | 460 | 460 | 460 |

| Počet programů | 1 | 20 | 20 | 20 | 20 |

| Maximální počet kroků v programu | 1 | 10 | 10 | 10 | 10 |

| Průměrná doba ohřevu až 180 ° C | 40min | 35min | 25min | 25min | 20min |

| Počet dveřních křídel | 1 | 2 | 2 | 2 | 2 |

| Diagnostika / aktualizace přes internet | ✖ | ✔ | ✔ | ✔ | ✔ |

| Počítadlo spotřeby médií | ✖ | ✔ | ✔ | ✔ | ✔ |

| Stropní prvky z nerezové oceli | ✖ | ✖ | ✔ | ✔ | ✖ |

| Přímé topení | ✖ | ✖ | ✖ | ✖ | ✔ |

| Uzávěry odolné proti výbuchu | ✔ | ✔ | ✔ | ✔ | ✔ |

| Silikonové těsnění dveří | ✔ | ✔ | ✔ | ✔ | ✔ |

| Cenová skupina | 1/2 | 2/5 | 4/5 | 5/5 | 3/5 |

Technology

|

Gravitational heating system Thanks to the use of a gravitational heating system in the SPARK gravitational furnaces, we can boast of a good result of temperature uniformity, our tests have shown that the uniformity of air temperature in our gravitational furnaces, with the appropriate arrangement of elements, does not exceed ? 5 ° C! We owe the result to our heating element assembly technology. |

|

Quick heat up In the SPARK gravitational furnaces, specially designed heaters are installed that quickly give off heat, thanks to which our furnaces heat up quickly. Fast heating is due to the seals and insulation used, the specially profiled gasket does not contain asbestos and is safe for the user. Insulation optimization, b no contact between the furnace chamber and the casing minimizes heat loss and saves power. Our ovens, depending on the model, heat up at a speed of up to 8 ° C per minute . |

|

|

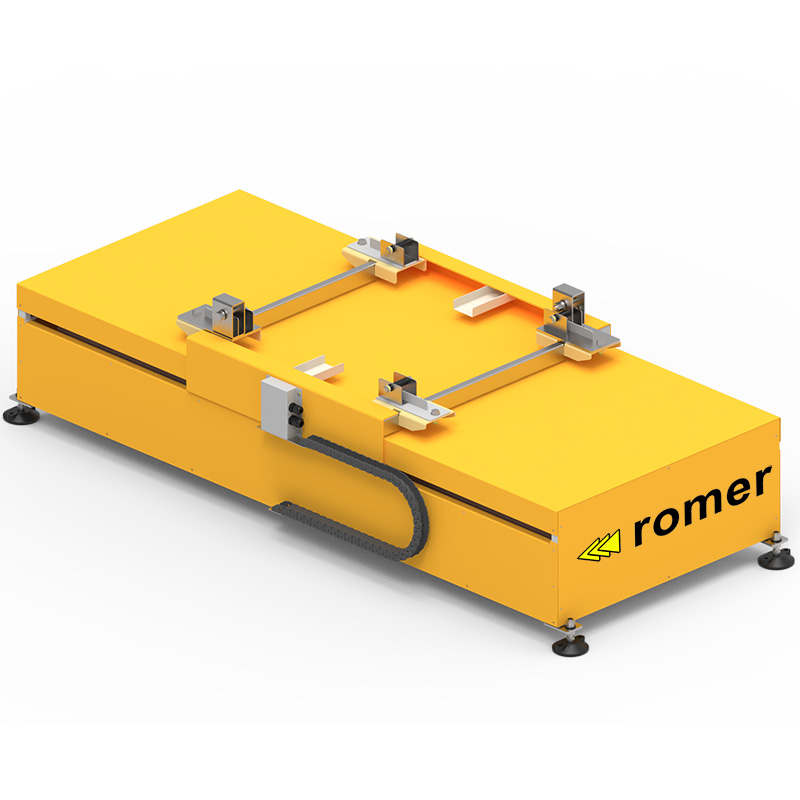

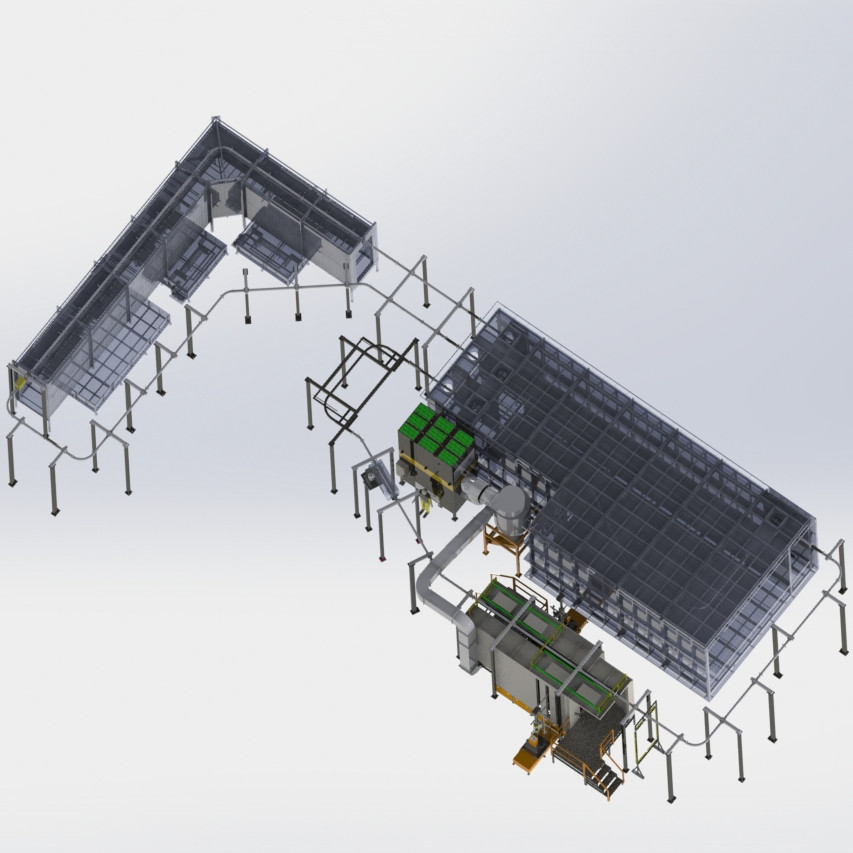

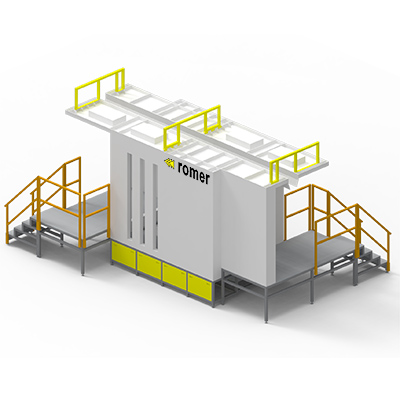

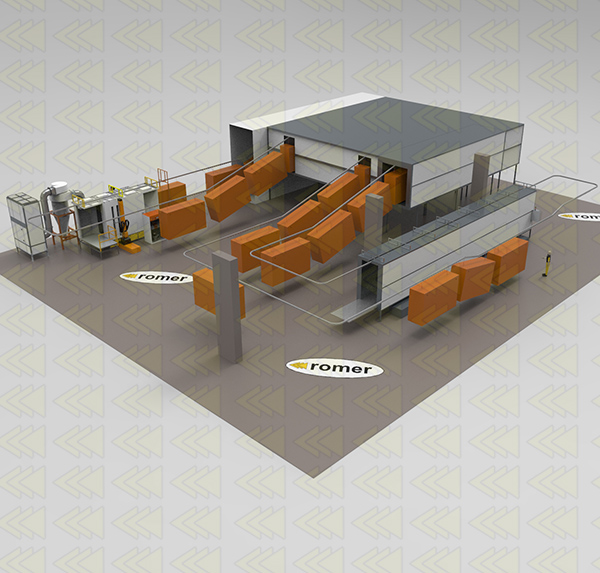

Transport system SPARK kilns are standard equipped with two lower transport trolleys. In response to the market demand for inexpensive solutions, we have developed a manual bottom transport system that allows you to transport large-sized items with a small amount of force. Our system allows optimal use of the entire surface of the furnace and ensures high cleanliness of painted elements. Thanks to the use of two trolleys, the trolley moving around the hall does not contaminate the interior of the furnace. The upper trolley is used for the very entrance to the kiln. The use of one trolley introduces dirt from the floor into the furnace chamber, our system eliminates this problem. |

|